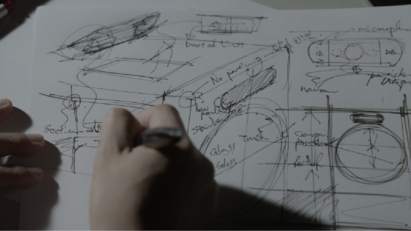

LG’s Home Appliance Design Principle: A Commitment to Customer-Centric Innovation

Good product design is all about understanding and meeting customers’ needs. As a leader in the home appliance industry, LG integrates ‘customer-centricity’ into every stage of the design process to ensure its products deliver a more convenient and emotionally satisfying user experience. The company continues to show the way forward, making innovative appliances and smart home solutions for a better life based on its ‘3F’ design philosophy.

The Essence of 3F: Fit, Feel, Finish

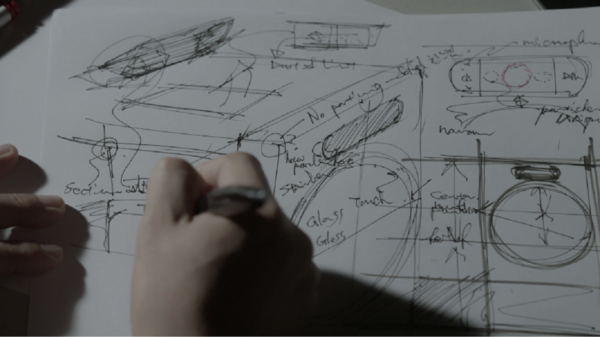

“LG uses the term ‘3F’ to refer to the appearance, performance and other tangible and intangible qualities of its products experienced by the customer,” said Chung Wook-jun, vice president and head of H&A Design Lab at LG Electronics’ Life Innovation Design Center. “In essence, 3F is a set of principles that guides the company as it weaves the core values of completeness, ease of use and emotional satisfaction into each product it makes.”

3F stands for Fit, Feel and Finish. ‘Fit’ refers to seamless (zero gap) product design and overall design uniformity, while ‘Feel’ encompasses the smooth and resilient operation of moving parts as well as the satisfying feedback that interfaces, doors and other components provide when handled by users. ‘Finish’ focuses on matching the right colors with the right materials and achieving a clean, consistent aesthetic across product lines. The definition of 3F has gradually expanded over time and now extends to elements such as ergonomics, user experience (UX) optimization and user interface (UI) usability.

Officially introduced in 2001, 3F is now deeply ingrained in the way LG works. The company even formed a specialized organization to focus on 3F, which collaborates closely with several departments – including product planning, design, development, quality control and sales – to maintain a cohesive approach to customer-centric design.

Customer-Centric Design Research

The core aspect of 3F work is to guarantee the completeness of every product LG develops. Through securing a high level of completeness in the development phase, the company helps to prevent potential quality issues from arising during production.

At the concept planning stage, LG identifies and addresses any deficiencies or inconveniences associated with previously released models to prevent their recurrence in new products. Using its own internally developed ergonomic standards, the company thoroughly evaluates products for ease-of-use and to determine if further improvements are needed. Prior to finalization and mass-production, LG re-evaluates its products using up to 160 different criteria to assess whether completeness has been achieved.

When a prototype is produced at the design verification stage, it is tested under actual usage conditions. Data-driven feedback derived from these tests – such as the precise measurement of the force needed to open an appliance’s door – enables the relevant departments to make necessary adjustments.

Quality testing at LG involves extensive processes to ensure products meet usage and reliability standards. Should a product fail any test, LG carefully identifies and addresses the root cause of the issue. Subsequently, the product undergoes hundreds of additional tests until it meets the company’s exacting internal standards. Multiple methods are employed to confirm that each unit produced matches the usability and reliability standards set during the development phase. The data gathered throughout these various processes is meticulously analyzed to refine future designs.

Subtle Details that Reflect LG’s 3F Design Principles

The recently launched LG SIGNATURE washer/dryer exemplifies the company’s commitment to its 3F design principles. Manufactured using the same methods employed to produce luxury goods, the washer/dryer successfully delivers the ‘high-end’ aesthetic and feel of LG’s original design concept. The attention to subtle details that is so much a part of 3F design can be seen in the dryer’s filter grip, which has been designed in accordance with knuckle-width studies and numerous customer acceptance surveys to provide optimal usability.

To enhance the sophistication and operability of the control knobs applied to its washing machines, LG conducted a comprehensive range of 3F research initiatives and even developed its own custom measuring equipment. The company’s efforts led to the creation of a control knob reminiscent of the center-console control dials found in luxury automobiles, providing a pleasingly premium look and feel while also contributing to a better user experience in both a practical and emotional sense.

Introduced last year on select LG refrigerator models, the Auto Soft Closing System is another example of LG’s customer-centric 3F design. The system uses dampers to ensure that the refrigerator door closes softly and quietly, enhancing usability, convenience and customer satisfaction.

The 3F design principle, which reveals LG’s strong commitment to the pursuit of perfection, is intertwined with another uniquely LG concept: ‘Affection-ism.’ Affection-ism could be described as a ‘design mindset,’ centering on caring for customers via the delivery of ‘Uncompromising Customer Experiences,’ ‘Human-centered Innovation’ and the ‘Warmth to Power a Smile.’ By staying true to its core values and customer-first philosophies, LG will continue to provide products that exceed expectations and make everyday life that much better.

# # #

![[Executive Corner] Product Design, the Start of the Consumer Experience](https://www.lgnewsroom.com/wp-content/uploads/2022/10/Design-Center_fi-e1667269040175-403x272.png)