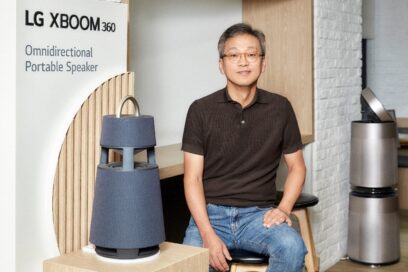

[Executive Corner] DX for the Company: Innovation in the Way You Work

Lee Sam-soo, Chief Digital Officer at LG Electronics

To bring innovation to every point along the value chain, and ultimately provide maximum and differentiated value to customers, LG is actively engaging in an organization-wide digital transformation (DX). To accelerate the transformation process related to customer experience, LG established the new Chief Digital Office (CDO) division last year. An innovator by nature, LG is changing the way it works, utilizing data and technologies, including AI, to increase efficiency and reduce costs from manufacturing and quality, to purchasing, supply chain management (SCM) and customer support (CS). By encouraging and implementing innovation at every level, LG will not only achieve the above goals, but also be better able to identify and upgrade all aspects of the customer experience (CX).

To fully understand the needs and wants of customers, LG created AI- and data-based solutions that are helping the company refine the CX right from the very outset, from product and service planning to the development stage. When LG launches a product or service, the New eXperience Introduction (NXI)* process is applied to monitor whether the CX is being delivered as intended. This internal process is an innovation that will greatly improve the value of diverse offerings and brand moving forward.

Based on the company’s experience implementing these programs and systems so far, LG has some recommendations for adopting innovative DX solutions to create better ways of working and CX outcomes.

For companies with legacy to successfully promote DX to internal audiences, identifying key business challenges that can be solved using technology – better known as ‘low-hanging fruit’ – must be a top priority. These low-hanging fruit always exist within any company. So, rather than jumping into projects that seek to change everything or run for multiple years accumulating ever-greater amounts of data, LG identified and focused its energies on points that can be solved now using current AI and data capabilities.

Once identified, it can be divided into two categories: ‘DX for the Company’ and ‘DX for the Customer.’ The former relates to innovation in how an organization works, while the latter refers to innovation in the overall CX space. Introducing any form of ‘DX for the Company’ can be a challenging undertaking, especially where older organizations are concerned. This is because any company with a long history is more likely to have its value chain fixed in the same way it always has been. However, if a company’s methods of working across all areas of the value chain – including development, manufacturing, purchasing, quality and SCM – have remained static for a long time, or there has only been gradual improvements made over time, there is a strong possibility that the application of digital technologies, such as data analysis and AI, will produce meaningful results.

LG is undertaking various company- and customer-targeted DX initiatives and is already seeing excellent results in both spheres. Recently, LG Smart Park in Changwon, South Korea was selected as a Lighthouse Factory by the World Economic Forum (WEF). The WEF confers this designation on facilities that are implementing Fourth Industrial Revolution (4IR) technologies, such as the Internet of Things (IoT), big data and AI, to usher in the future of manufacturing today.

LG’s “Digital Twin” technology is one of the key factors in LG Smart Park being named a Lighthouse Factory. It collects and analyzes data from the factory and its many production lines every 30 seconds, enabling it to accurately predict if any issues will occur up to 10 minutes in advance and restock any parts or materials before they run out. Each assembly line at LG Smart Park is attached to an ‘intelligent warehouse,’ which monitors inventory in real time and automatically requests the re-supply of items needed to keep production running smoothly. Another 4IR innovation that sets LG’s facility apart is the use of 5G network-connected logistics robots that rove the factory floor, taking the most optimal path to transport parts and materials wherever they’re needed. Also, the company has managed to minimize product defect rates and avoid lengthy downtimes by leveraging big data analysis and AI prediction.

LG Smart factory is a success story of DX, its intelligent innovations resulting in a 20 percent boost in productivity, increased worker efficiency and a significantly lower product defect rate. Its impressive performance could well trigger the integration of further DX systems and technologies throughout the entire company, including in areas such as material procurement, product transportation planning, SCM, purchasing and sales. Verifiable success is, after all, the best way to promote any kind of change within an organization.

The application of DX to purchasing processes is especially meaningful due to the supply chain issues caused by COVID-19 and other globally impactful events. LG is currently developing an intelligent system to predict the price and supply volatility of components and essential raw materials. This will be an invaluable resource during pre-negotiations with suppliers, enabling the company to focus on data-based objectives rather than being guided by the intuition of individual managers. Market monitoring, prediction and scenario-response management all become much easier and less dependent on the capabilities of personnel when you add advanced, digital technologies into the equation.

There are many possibilities for and examples of enhanced performance via ‘DX for the Company,’ especially given that the inherent value of DX is not restricted to any particular industry.

Active exploration in the arena of ‘DX for the Company’ is highly recommended because there is already a variety of value chains and data that can be utilized to discover so-called low-hanging fruit. Furthermore, DX has been shown to directly improve key measures of corporate performance, including, but not limited to, productivity and profitability. Whether speaking in financial or qualitative terms, the positive effects that DX can have are relatively easy to communicate to internal stakeholders, which is helpful for increasing buy-in and reducing resistance. In areas such as manufacturing, purchasing and quality, where there already exists an expectation that improvement activities will be regularly introduced, the task of promoting DX becomes, in most cases, even easier.

Lastly, it needs to be emphasized that, beyond the improved performance of an individual organization, the true success of ‘DX for the Company’ will come when these new methods and systems of working have spread to workplaces and corporations all over the globe.

Of course, change management is a key part of ensuring a smooth DX. LG have adopted the ‘10X’ (or ten-times) method to ensure a consistent process of reorganizing its working methods and systems until the requisite changes have clearly and verifiably been made. It’s about expanding the company’s efforts by 10X (or more) in a way that makes sense, with each change building upon the last with an express purpose and goal in mind – not merely change for the sake of it, but to streamline processes and add value in as many ways as possible. Scalability is another part of it, as companies want to be able to develop flexible platforms that can grow with its needs and ‘bend’ in accordance with shifts in the market and consumer demand. With effective change management and the consistent implementation and proliferation of targeted actions, companies can realize the envisioned DX in its totality.

LG believes that an accumulation of successes across the various areas of ‘DX for the Company’ will act as a strong foundation for a successful ‘DX for the Customer.’ By using DX to bring about innovation in the way we work, LG can greatly expand the scope and value of the CX and, in doing so, deliver even more innovative experiences to its diverse customers worldwide, helping to bring about a better life for all.

This story was edited from an editorial feature article published in The Electronic Times. Stay tuned for Part 2, titled “DX for the Customer: Innovating the Customer Experience with Data”.

By Lee Sam-soo, CDO at LG Electronics

# # #

* In 2022, LG replaced its previous product-oriented development process, known as ‘New Product Introduction’ (NPI), with ‘New eXperience Introduction’ (NXI), a more customer experience-oriented process.

![[Executive Corner] Exceptional and Unparalleled Customer Experiences LG Pursues](https://www.lgnewsroom.com/wp-content/uploads/2022/09/Executive-Corner_Customer-Experience_fi-401x272.png)

![[Executive Corner] A New Era of Customer Experience](https://www.lgnewsroom.com/wp-content/uploads/2022/08/Executive-Corner_CX-403x272.jpg)

![[Executive Corner] Innovation Partner for Future Mobility](https://www.lgnewsroom.com/wp-content/uploads/2022/01/exe-corner-img-FI-403x272.png)